Scale model builder Gertjan Veld has finished his next project of building a custom:

- Caterpillar D25D Articulated Dumptruck

DJB Engineering Ltd was founded in 1973 in Peterlee, County Durham in England by David John Bowes Brown.

The Firm built its first Articulated Dump Truck (ADT) a model D250 in 1974, based on a Caterpillar drive train. The trucks were marketed exclusively through Caterpillar dealers world wide as the major components were all Caterpillar.

The range was expanded and sales grew steadily with Caterpillar buying the rights to the design & branding them as Caterpillar DJB in 1985 and eventually buying the company out in 1995.

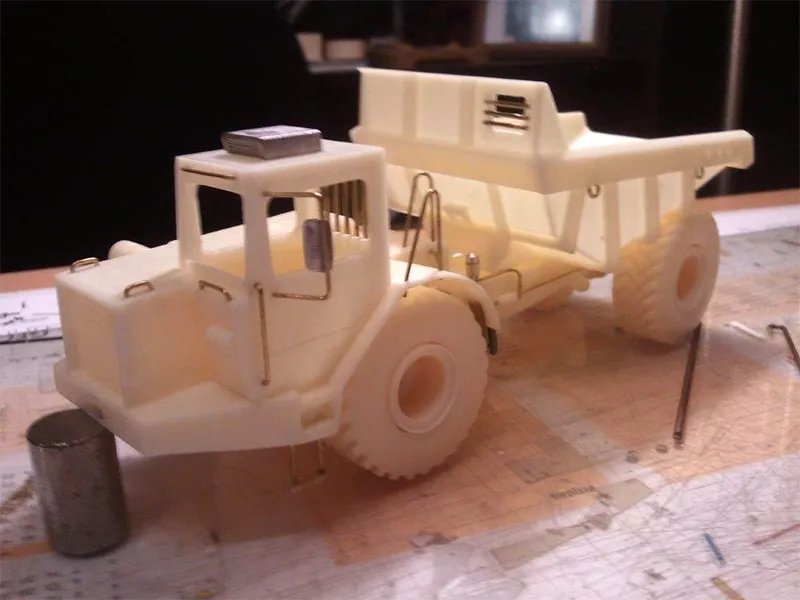

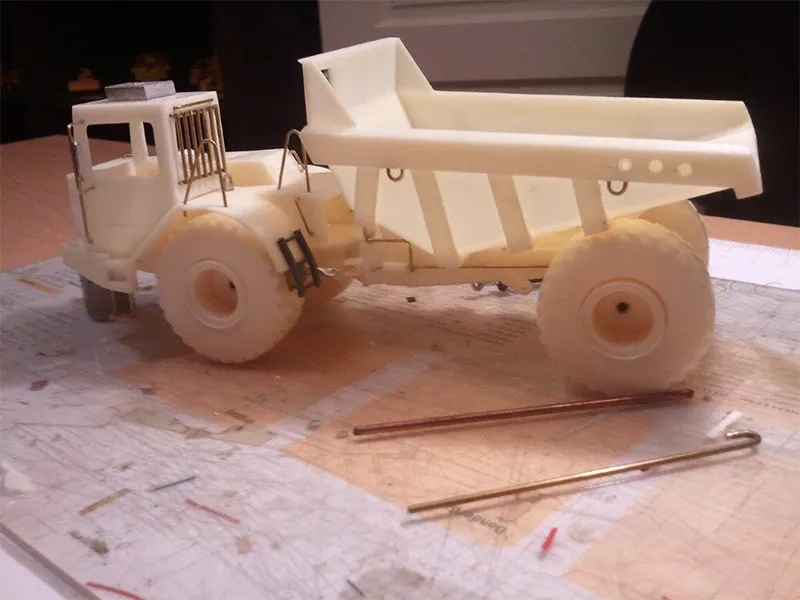

It is our goal in this Making-of Caterpillar D25D Articulated Dumptruck to show how this custom model has been achieved.

Gertjan shares his building skills through the photos with little notes guiding us in the construction process. Gradually it shows the making of a unique model by using the resin Kit from CypModels in 1:50th scale to create his Caterpillar D25D Articulated Dumptruck.

Enjoy reading & watching!

Gertjan and Wouter

The Kit

The parts

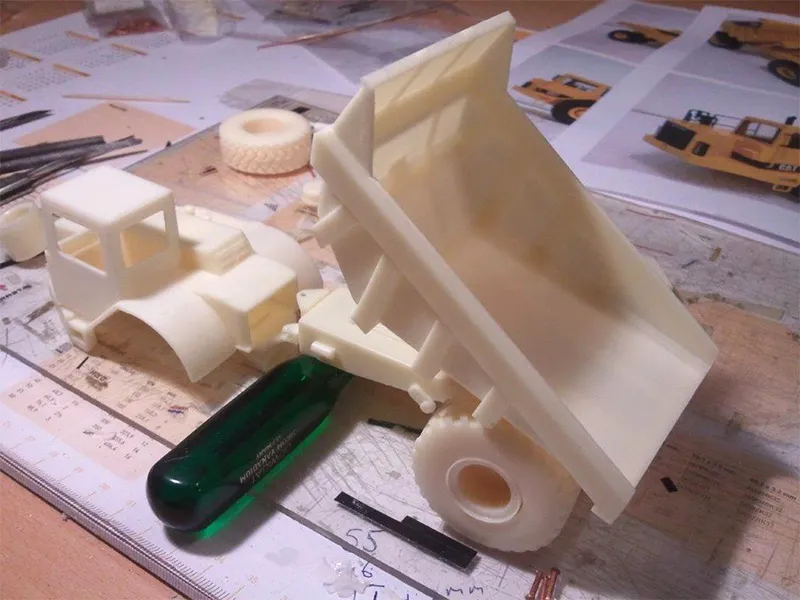

After the kit is unpacked follows the first inspection to check if all parts of the Caterpillar D25D Articulated Dumptruck are present. Secondly each individual component is checked very accurate and made ready for building and if needed this includes mainly the very careful filing of excess molding material and making all the parts so that they can be later joined together without any fitting problems.

Also in this 1st round all the individual parts are been thoroughly cleaned and degreased for the first time.

The Body

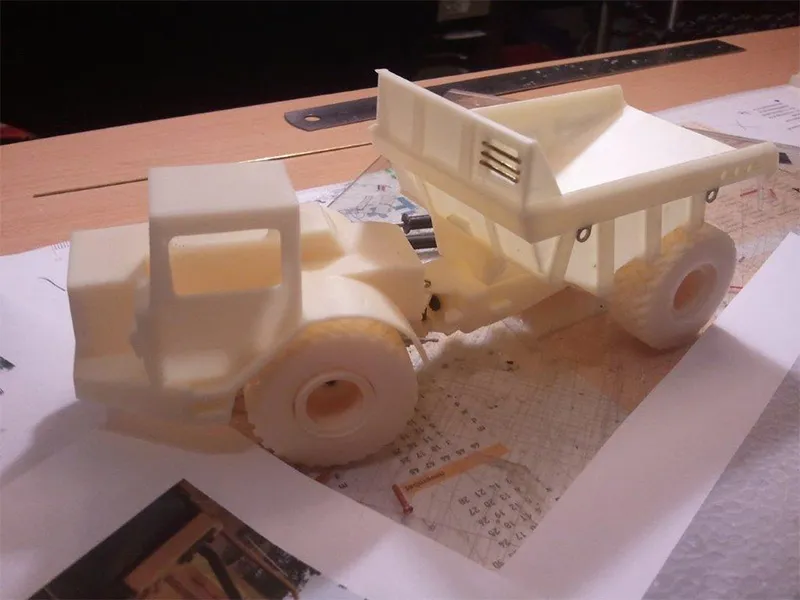

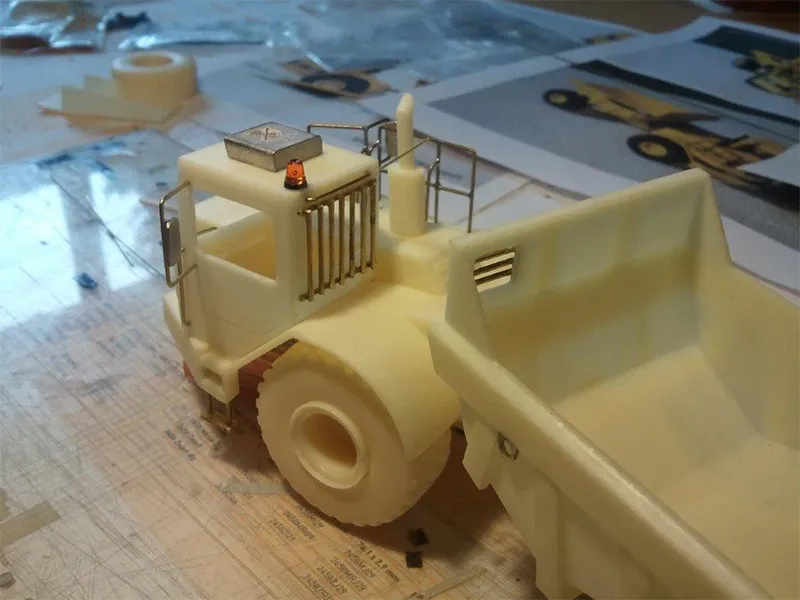

The actual construction begins with the first modifications to the Body.

The Body is among other things provided with two tongues lifting eyes on both sides of the Body. The headboard has on the side where the cabin is located ??a sight hole. This sight hole is equipped with slats made ??of brass to prevent (excess) material fall through into the cabin, however does give the Operator a much better view towards the rear.

Subsequently in this step, in the upper beam of the vehicle body on both sides, three holes are drilled that replicate the outlet holes of the Body heating. (Body heating prevents wet and cold load adheres to the inside of the body and thus ensures that the volume body remains optimally)

The rims and the lifting cylinders

To let rotate the two axes smoother in each wheel the existing hole for the shaft slightly larger drilled and is provided with a small hollow brass tube positioned so that each axle can now turn around without any resistance.

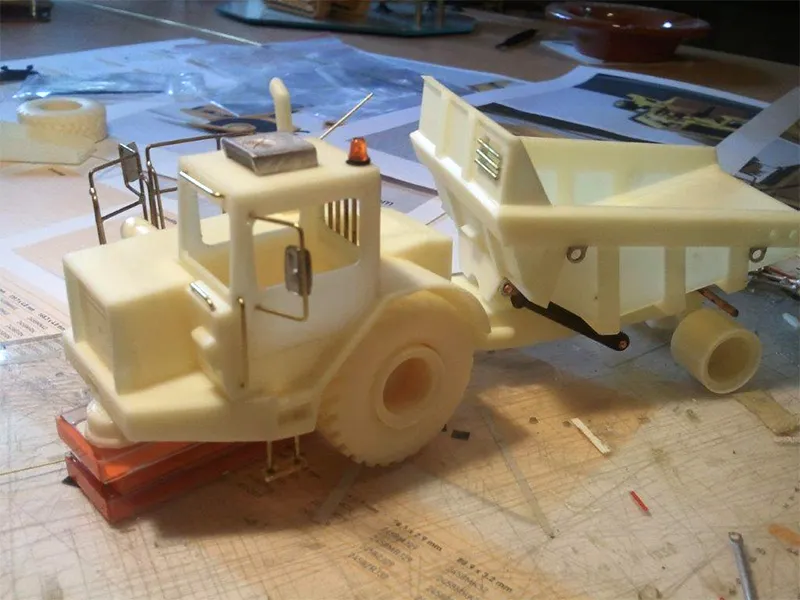

With the original Kit two lifting cylinders are supplied for the body, but nevertheless Gertjan decided not to use those but to replace them with two homemade lifting cylinders in the construction of this custom model.

The Details

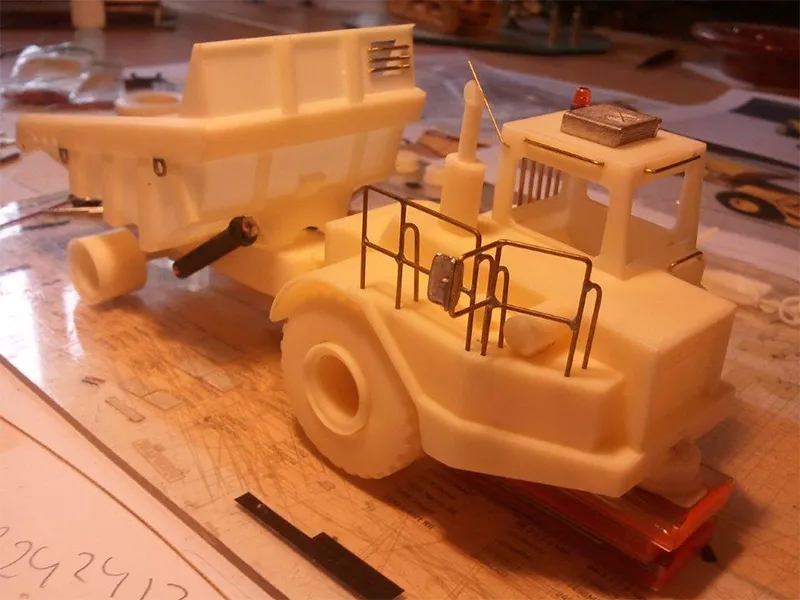

In the original kit are already plenty of extra little details to build included to make your scale model of the Caterpillar D25D Articulated Dumptruck realistically. But as befits a true custom builder Gertjan of course takes it one step further:

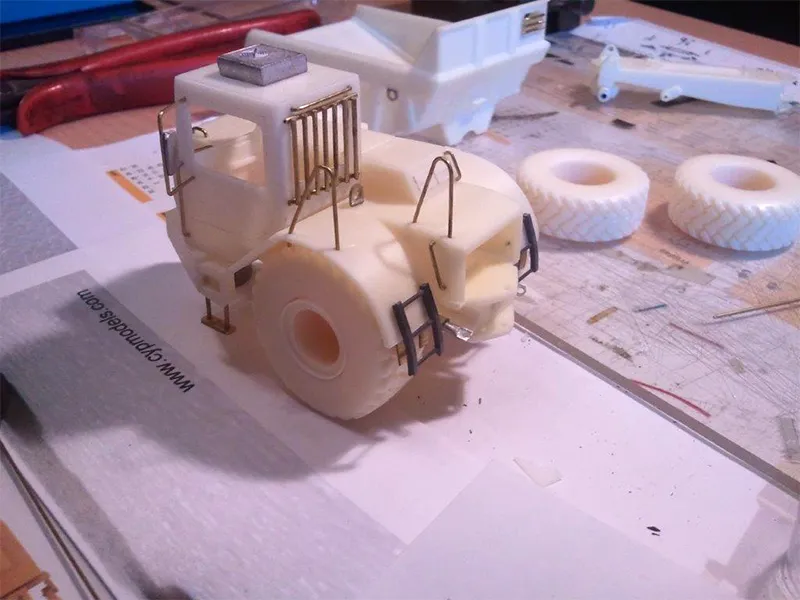

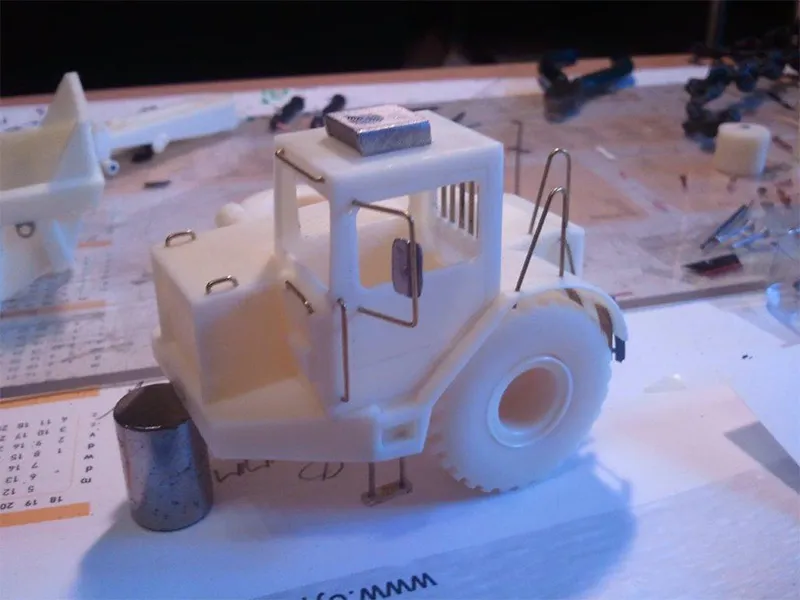

Added are the necessary (brass) handles on the cab and the engine unit. On the roof of the cab are added a (white metal) air conditioner, (plastic) flashing light and a miniature CB antenna.

The (brass) mirrors left on the motor unit and the ones right of the cab provide the required view in securing backward driving under a hydraulic Excavator at the loading location.

A loose (brass) stirrup step on the side of the cabin there so the operator can easily enter the cabin and (brass) grille slats to the rear of the cab provide protection against falling cargo during loading or while driving.

Also at the rear of the motor unit (brass) step rails and handles and railings are installed. Also the (brass) lifting eye on the motor unit, positioned behind the cab, is not lacking.

The body gets on each side two (brass) lifting eyes and the flap holders are also be placed on the both fenders of the motor unit.

Along the frame of the Body the required (brass) hydraulic pipes are installed.

The last step of the build-up phase is to test fit all the original and customized parts and after this finall test to clean up all the parts again with some lukewarm warm water provided with a little ammonia for degreasing.

We are now ready for spray work!

The painting of the parts

Done!

The model is done and now "Ready for work" and can be added to the collection in the display cabinet.